Buildern’s 2026 Construction Technology Report: Adoption Rates and Key Insights

What if the most conservative industry became the most innovative? You are right if you thought of the construction industry.

Today, construction technology is moving from “interesting new tricks” to the adoption of advanced technology in daily operations. It is no surprise that AI in construction and automation is changing the industry. However, now we see new application cases every week that seemed impossible last year.

In my blog article, I will discuss some directions of the construction technology (including AI, of course) and how they transform the way builders work.

Table of Contents

- Digital Leap in Construction

- #1 AI in Construction

- #2 Autonomous Material & Equipment Logistics

- #3 Collaborative Robotics (Cobots) with Human Workers

- #4 Innovative Materials

- #5 Modular Construction

- #6 Sustainable Technologies

- #7 Augmented Reality

- New Normal in Construction Technology

Digital Leap in Construction

Digital transformation has reached the construction industry as well, with more builders investing in digital tools. The size of the shift is clear when you see the market growth. For instance, the construction software market, according to some reports, is projected to grow to 21.03 billion by 2032.

More builders are investing in digital tools than ever before. Across every sector, from residential construction to large-scale infrastructure. This recent growth hasn’t happened in a vacuum. Some factors contribute to adopting new technologies:

- Labor shortages, one of the key challenges in the construction industry. They force companies to find automation, and the “workforce multiplies.”

- Sustainability goals that demand better material tracking and energy-efficient design with AI.

- Availability of advanced AI tools to a wider range of companies.

Ultimately, tech adoption is now a strategic necessity, not a luxury. But what’s actually driving this growth on the ground? Let’s discuss some of the biggest trends that are moving data from the office to the jobsite.

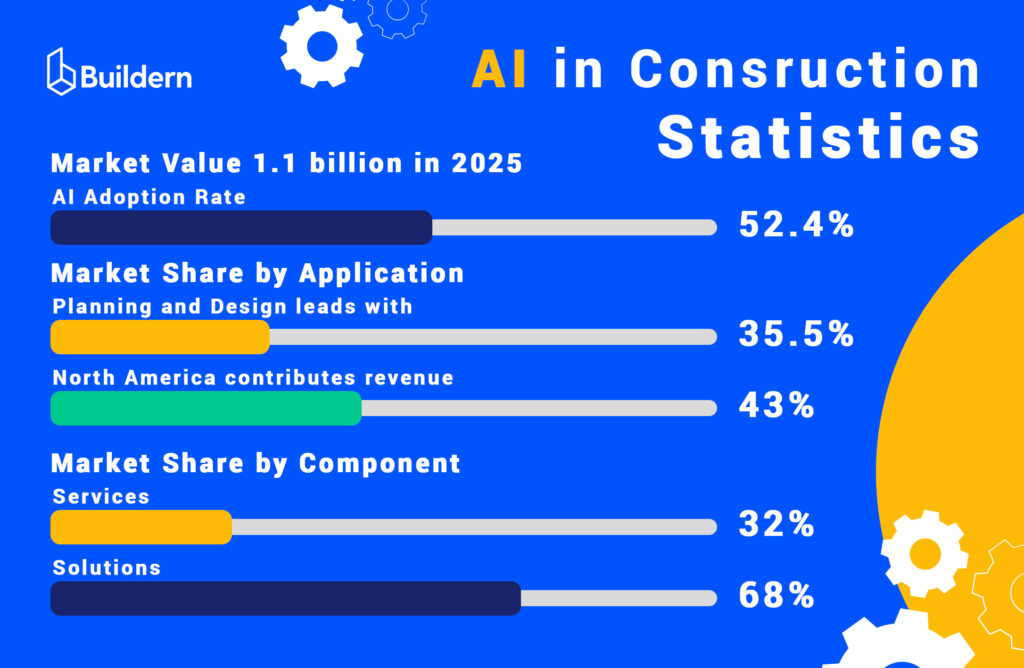

#1 AI in Construction

AI in construction is no longer a “future tool” as it has become a tangible part of today’s workflows.

On the field side, AI‑powered equipment, drones, and IoT‑sensored machinery now enable monitoring, hazard detection, autonomous movement, and material tracking. For example, excavators and haul trucks are increasingly fitted with AI‑driven sensors and GPS to “see” obstacles and adjust their paths proactively.

Meanwhile, in the office, AI is used for generative design, automated billing, schedule optimization, and other tasks. Thus, we cannot just present AI as “one technology”. There are several layers that are equally important for construction.

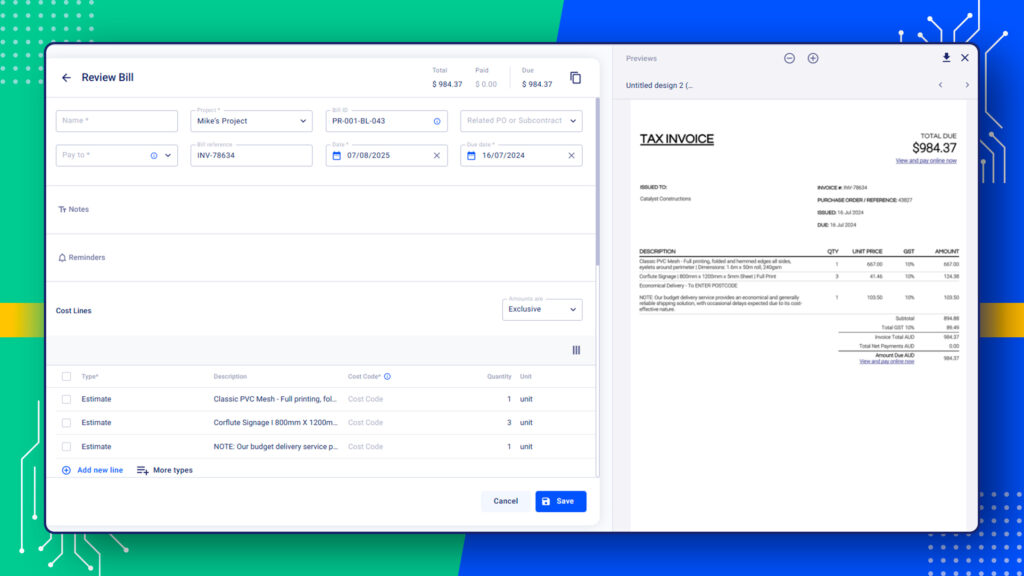

AI in Project Management

Project managers now have access to tools that can automatically generate schedules, estimates, and invoices. One practical example is AI-assisted billing I use with our software. Any file, regardless of the format (PDF, JPEG, etc), can be scanned, and key data, such as dates, line items, and vendor or sub information, appears in the construction software.

It means construction teams can focus on planning, problem-solving, and client communication instead of repetitive manual work.

In addition, the AI tools may serve as an assistance in finding relevant information on how to find features and the way they work in the project management software.

Agentic AI and Autonomous Decision-Making

The next application is agentic AI, which goes beyond assisting with tasks to making autonomous decisions toward specific goals.

For example, an agentic system could oversee a foundation pour or coordinate materials, and alert crews to changes without requiring constant human contribution. AI can dynamically adapt to changing conditions, from weather disruptions to supply chain delays.

There can also be a safety chatbot powered by agentic AI that goes beyond reminders. It predicts potential hazards, communicates with workers in real time, and recommends preventive actions. Those are just several examples of AI applications, but it’s difficult to say what is waiting for us in the future of construction.

#2 Autonomous Material and Equipment Logistics

These technologies transform how construction sites manage resources, reduce delays, and improve overall efficiency. Traditionally, moving materials, delivery coordination, and equipment management required human intervention.

In 2025 and during the next few years, AI-powered systems, robotics, and IoT-enabled equipment are likely to take over much of this logistical work.

Autonomous vehicles and drones can transport materials across large sites, navigate complex layouts, and deliver supplies directly where they are needed.

Sensor-equipped machinery communicates in real time with inventory systems and project management software, ensuring that every item is tracked from warehouse to job site.

AI-driven predictive analytics also plays a key role. It analyzes historical usage data, weather patterns, and project schedules to recommend when to use certain materials and how to optimize delivery routes and equipment deployment.

It does not mean that humans are not needed at all, as many of us fear. Simply, the logistics manager will save time on routine processes and will rely on the analysis by AI-powered systems received in minutes instead of doing it manually for weeks.

#3 Collaborative Robotics (Cobots) with Human Workers

These robots are designed to work alongside human workers to bring more safety and efficiency to the construction sites.

Unlike traditional industrial robots that operate in isolation, cobots are built for interaction, assisting humans with physically demanding tasks. They work as helpers, leaving critical decision-making and oversight to their human partners.

Cobots can perform a variety of construction tasks, such as lifting heavy materials, placing bricks, welding, or assisting with assembly. One of the key advantages of cobots is safety. Advanced sensors, computer vision, and AI allow cobots to adapt their actions in real time, to detect human presence, and avoid collisions.

What does it mean for the construction industry? Integrating cobots will allow teams to have better safety levels at the site and to maintain higher productivity levels.

#4 Innovative Materials

Innovative materials bring new technology and sustainability into the mix. One leading example is self-healing concrete, which incorporates mechanisms that allow cracks to repair themselves, reducing maintenance and extending asset life.

Traditional concrete may cause micro-cracks and deteriorate over time. Meanwhile, with self-healing variants, there will be no such problems.

Some materials, such as smart glass adjusting its transparency based on sunlight or temperature, or solar glass, generating clean energy, are already used. However, they are mainly applied when it comes to large construction projects.

While these technologies are commercially available, others, such as phase-change materials and aerogel insulation, are still moving to mainstream adoption.

Phase-change materials stabilize indoor climates by absorbing and releasing heat, and aerogel offers exceptional thermal performance in lightweight panels.

It’s likely that those materials currently used as niche tools will go mainstream and will gradually become standard building practice accessible to typical projects.

#5 Modular Construction

It’s a technology that is not new, but its path to becoming one of the defining trends of the next decade makes it worth mentioning.

Once, it was viewed as a niche or temporary solution. However, now it’s a common construction model. Moreover, by 2030, the global modular construction market is projected to grow by 7.9% annually. The sectors leading this growth include residential, healthcare, and hospitality.

These are industries that demand faster project delivery, tighter budgets, and consistent quality control.

Besides, not the notion of “modular construction” but what this format can achieve is

For example, digital twins, digital models of actual real-world construction, and AI-driven design are likely to simplify the process of modular construction. It will be easier to optimize layouts, automate production, and ensure accuracy.

As mentioned, robotics also helps in implementing these tasks by taking over repetitive assembly challenges.

#6 Sustainable Technologies

If we consider the technologies already discussed, you can see that they are all closely connected to the drive for sustainable construction. Each of them is connected to the need to reduce carbon emissions, minimize waste, and optimize energy use. Modular construction or innovative materials serve this purpose.

For instance, cross-laminated timber and mass timber construction have emerged as alternatives to concrete and steel. It’s even for mid-rise buildings, with fire safety concerns largely resolved through improved engineering and code updates.

The critical shift by 2026 isn’t the invention of new sustainable technologies but rather their normalization and use in many projects. What was once a “green building” will be just a “building”. In some cases, sustainable building technologies may be more mandatory rather than voluntary.

#7 Augmented Reality

AR allows architects, engineers, and contractors to visualize complex structures in real time. In the past, the designers used 3ds Max and similar tools to show how their house would look.

Now on the jobsite, AR headsets or tablets can display 3D models directly in the construction area. The workers can see exactly where components should be installed, identify potential clashes before they occur, and verify measurements instantly.

AR also provides immersive simulations that help workers understand procedures and safety protocols. Besides, designers, project managers, and clients can walk through virtual models together and discuss changes. It’s obvious that in the coming years, this technology will be used on a larger scale.

New Normal in Construction Technology

As AI moves through all the industries, I can confidently say that in 2026, it will be a usual part of builders’ daily routine.

Of course, it depends on the scale of construction. Residential builders are likely to use it in the construction project management. Meanwhile, robots will work shoulder-to-shoulder with human crews on the sites of large builds.

Yet perhaps the most significant shift isn’t about any single technology but rather their convergence. Modular construction powered by digital twins. Sustainable materials tracked through AI-enhanced supply chains.

By 2026, the question will not be “Should we adopt technologies in construction?” but rather “How quickly can we scale them?” The builders who recognize the need to make changes and adopt technology at scale will remain competitive.

How Has Technology Changed Construction?

Technology is transforming construction to assist workers, not replace them. The industry remains traditional at its core, but innovation is changing how builders work. Large-scale construction projects increasingly use robots and innovative materials. Meanwhile, smaller residential projects are becoming more technology-oriented.

What Are Examples of Construction Technology?

Some technologies work at the site during the building process, while some can help enhance the workflow. There are different types of devices and materials. For instance, autonomous vehicles and drones transport supplies across large sites. Another type of technology makes construction processes smarter through digital solutions.

What Will Be Different About Construction Technology in 2026?

Construction technology is likely to shift from being an advantage to a necessity used in daily operations. The most significant change won’t be any single technology, but its mix. AI will also become a routine part of daily workflows, especially in project management, to simplify and make the processes faster and more efficient.

What is Green Construction Technology?

Green construction technology refers to innovations that reduce carbon emissions, minimize waste, and optimize energy use. There are different types of devices and materials, like smart glass that adjusts to sunlight and solar glass that generates clean energy. Cross-laminated timber and mass timber offer sustainable alternatives to concrete and steel.

How Can AI Help in Construction?

AI improves accuracy and the speed of implementing repetitive tasks across all project phases. It helps contractors analyze large datasets to generate estimates, scan invoices, and manage costs more effectively. On the job site, AI-powered drones and sensors monitor progress and safety conditions in real time.